Features

Sample Report

Seamless Integrations

Microsoft Office

Export packaging instructions directly to customizable Excel and Word templates for fast, professional documentation.

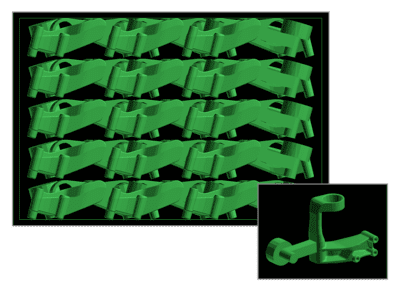

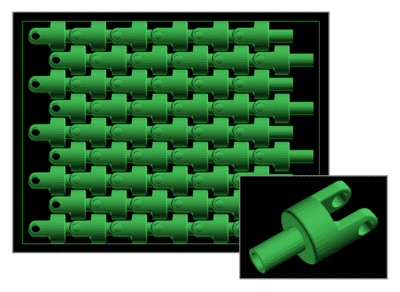

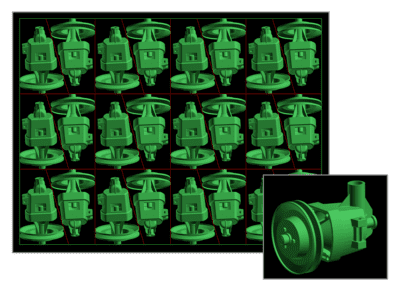

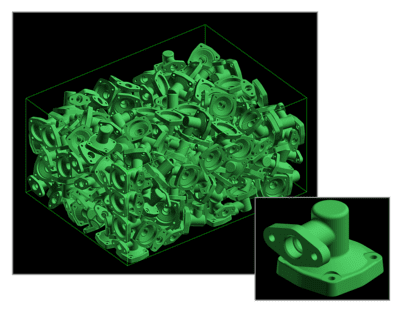

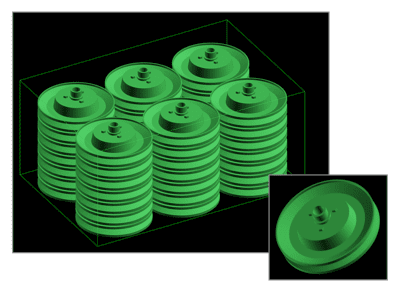

3D CAD Compatibility

Generate CAD outputs in JT, STEP, and VRML formats for detailed 3D visualizations in your preferred viewer—ideal for technical reviews and client presentations.

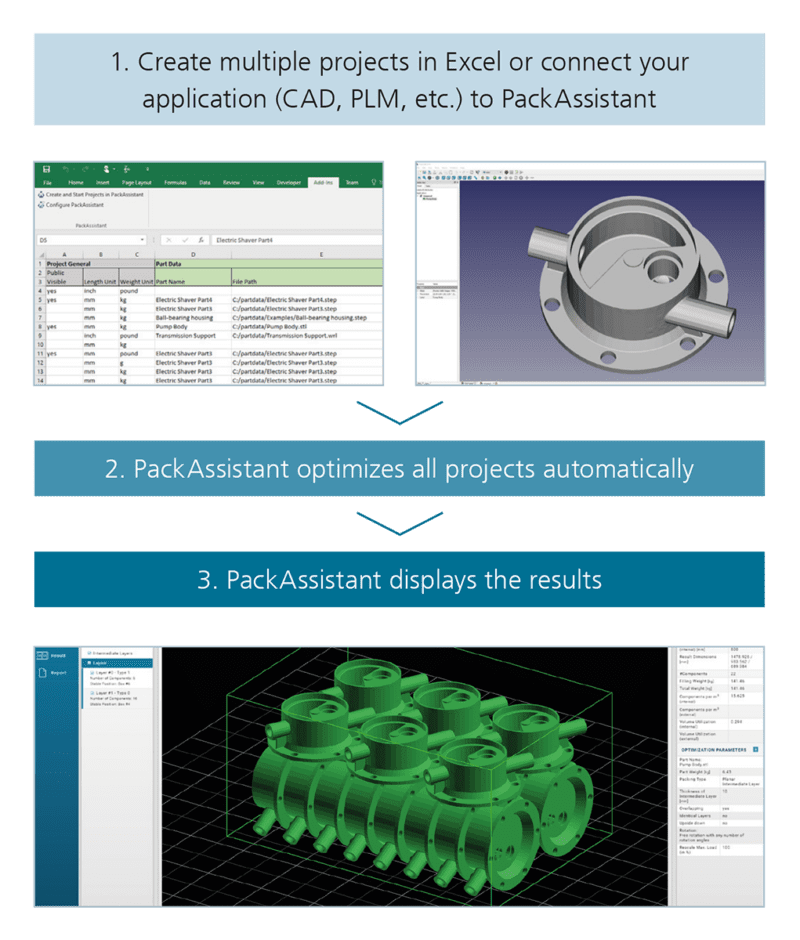

Automation & Workflow Integration

Streamline your process with our JSON-based interface, enabling full automation and integration with ERP, PLM, and other business systems.

Includes an Excel Add-In to create and optimize PackAssistant projects directly from spreadsheets.

Add-on Module for PackAssistant Automation

At A Glance

Excel Add-In:

Direct Interface Access: